3D Printing Basics and Understanding Market Terms

Patient-specific solutions have become more prominent within the past few years in dentistry; because there’s no one-size-fits-all solution for dental restorations. Many dentists and dental labs have come to resort to tech and savvy ways of treatments. 3D printers provide an ideal fit for dentistry because it allows dentists to make surgical guides, crowns, implants, and trays quickly and cheaply. 3D printers remove the alginate impression process and replace that process with intraoral scanners, which create a digital impression file of the patient’s mouth, which can be uploaded into any software and then printed right then and there. 3D printers have, in recent years, become more affordable for all clinicians, creating new treatment plans for all patients.

Yet amid all the exciting developments in 3D printing, finding the right 3D printer for your practice can be tedious and vexing. Investing in a 3D printer requires a deep consideration into its parts and knowing what you desire from your office workflow. By understanding the components of any 3D printer you see on the market, you can gain a deep appreciation for the technology out there and know what you want in return.

Top 10 Dental X-Ray Supplies & Equipments

3D Printer Basics

3D printers require accuracy, speed, and ease to be effective in any office setting. Today, 3D printers operate with three different technologies that influence dental practices: Stereolithography (SLA) and Digital Light Processing (DLP).

- Stereolithography – SLA uses a laser beam across a print area, using liquid resin and solidifying it in specific areas to form and design. SLA printers direct the UV laser to the correct x and y coordinates to trace out the cross-section model, keeping the laser in constant motion and making it more suitable for printing multiple, large intricate parts in one go. SLA laser lights, however, are typically more expensive to replace and make the machine more expensive as a result.

- Low Force Stereolithography – A newer category of stereolithography, LFS reduces the strain of peeling the model from the resin tank by creating a more flexible tank and a scalable light processing unit. The tank contains film which bows gradually to reduce pressure built up during the extraction process. The LPU uses lights and mirrors to control the linear illumination of the laser light, directing it opposite of the building plane for more accurate parts.

- Digital Light Processing – DLP incorporates the same mechanics as SLAs and LFS but instead uses a digital processor as a light source to solidify the resin. The digital processor remains stationary and cures the resin a layer at a time. This creates a faster printing time and allows the operator to control the intensity of the light source on the resin. Because of its simpler design, the light source can be more easily replaced and costs less.

- Fused Deposition Modeling – Also known as an extrusion process, or FDM for short, FDM produces dental applications at a reliable rate by extruding melted filaments layer by layer and fusing them together, giving it a wide versatility with materials and a bigger budget. However, due to it being the most common form of 3d printing, it’s also the least accurate and requires more post-processing to fix imperfections.

When evaluating 3D printers, understanding how the light source works in each model is the key to finding the best 3D printer for your practice. Laser SLAs tend to draw the lines with the light. LFS printers minimize the laser spot size when producing the product, and draw the model in smaller increments for more consistent accuracy. DLP printers use the projector screen to draw the layers by pixels, and the smaller the pixel size, the more accurate the end result is. Most modern printers have an intuitive design to them thanks to company’s and their reliable customer services, such as software tools, automatic resin dispensers, and even their own select solutions to wash off the solvent from the resin.

Top 5 Dental Surgical Instruments Manufacturers

1. Pro95 Printer by SprintRay

Product Description

The Pro95 Printer by SprintRay is a high-performance 3D printer designed specifically for dental applications. With more than twice the printing capacity of its predecessor, the MoonRay S, it allows dental professionals and lab technicians to produce multiple appliances in a single build with enhanced precision and ease.

Product Overview

This printer features cloud-connected software that automates workflows and simplifies the printing process, reducing the learning curve for new users. The integrated DLP projector and a print volume of 190 x 100 x 200 mm offer substantial output, while the minimum feature size of 95 microns ensures fine, detailed results. Its STEM (Selectively Textured Elastomeric Membrane) tank technology reduces resin adhesion for smoother, more reliable prints.

Key Features

Over double the capacity of the MoonRay S

Cloud-based software for automated workflow

Integrated DLP projector for precision printing

Large build volume: 190 x 100 x 200 mm

Minimum feature size: 95 microns

STEM tank minimizes adhesion and improves reliability

Magnetic safety sensors for added protection

Compatible with a wide range of dental resins

Common Applications

Printing dental models and appliances

Creating aligners, retainers, and surgical guides

Use in dental clinics and laboratories

Batch production of customized restorations

Technical Specifications

Manufacturer: SprintRay

Product Type: Dental 3D Printer

Build Volume: 190 x 100 x 200 mm

Minimum Feature Size: 95 microns

Tank Technology: Selectively Textured Elastomeric Membrane (STEM)

Connectivity: Cloud-connected software

Safety: Magnetic lock sensors

Compatibility: Multiple resin types

Customer Ratings

Rating: 4.9 out of 5 (Based on verified reviews)

Customer Feedback

Exceptionally accurate results

User-friendly interface and software

Ideal for high-volume dental practices

Fast, clean, and reliable print process

Top 5 Handpieces in Dentistry. High-Speed and Slow-Speed

2. SolFlex 170 by Voco Dental

Product Description

The SolFlex 170 by Voco Dental is a compact, high-efficiency 3D printer tailored for orthodontic practices. Engineered for speed and precision, it includes intelligent sensor technology to monitor and adjust peeling forces during the printing process, significantly reducing overall print time by up to 40%.

Product Overview

Utilizing advanced DLP technology with a 385 nm chip, the SolFlex 170 produces dental appliances with high clarity, removing yellow tinting common in other printers. Its silicone-based Flex-Vat build tray reduces peeling forces and minimizes the need for excessive support structures, streamlining workflow and improving output quality. The system’s open print standard ensures compatibility with a wide range of materials and includes Voco’s Pyramis software for optimized control.

Key Features

Sensor-monitored laser optimizes peeling forces

Reduces print time by up to 40%

DLP technology with 385 nm chip for improved clarity

Silicone Flex-Vat tray for less peeling force and fewer supports

Compact size ideal for small practices

Open print standard for material flexibility

Includes Pyramis printing software

Common Applications

Orthodontic appliance fabrication

Clear aligners and dental models

Rapid prototyping in compact dental offices

Daily use in high-volume orthodontic workflows

Technical Specifications

Manufacturer: Voco Dental

Product Type: Dental 3D Printer

Technology: Digital Light Processing (DLP)

Light Source: 385 nm chip

Build Tray: Flex-Vat silicone tray

Print Optimization: Sensor-monitored peeling force adjustment

Software: Pyramis included

Material Compatibility: Open print standard

Customer Ratings

Rating: 4.8 out of 5 (Based on verified reviews)

Customer Feedback

Remarkably fast print speed

Excellent clarity and precision

Works well with various resin types

Perfect size and performance for smaller clinics

Top 5 Dental Instrument Distributors

3. Connex3 Objet260 by Stratasys

Product Description

The Connex3 Objet260 by Stratasys is a highly versatile 3D printer designed to streamline dental and laboratory workflows using advanced PolyJet technology. It is capable of printing three different materials simultaneously, allowing for complex, multi-material dental models and prototypes to be produced in a single print job.

Product Overview

Using a material jetting process, the Objet260 deposits photopolymer droplets and instantly cures them with UV light, layer by layer. The printer features multiple print heads that also jet a gel-like support material to improve surface finish and minimize peeling. With its ability to handle hundreds of material combinations—ranging in color, rigidity, and translucency—it’s a go-to solution for detailed and realistic dental appliance modeling.

Key Features

PolyJet technology allows multi-material printing

Prints three materials in one build

Supports hundreds of color and material combinations

Material jetting with UV light solidification

Uses gel support material for cleaner curing and minimal peeling

Ideal for dental, medical, and design prototypes

Includes dedicated operating software

Common Applications

Multi-material dental model creation

Color-accurate prototypes with variable translucency

Detailed restorative and orthodontic planning

Educational and research applications in dental labs

Technical Specifications

Manufacturer: Stratasys

Product Type: PolyJet 3D Printer

Technology: Material Jetting with UV curing

Material Capacity: Prints three materials simultaneously

Support Material: Gel-based support for enhanced surface quality

Build Axis: X-axis multi-head printing

Software: Dedicated proprietary software included

Material Compatibility: Hundreds of rigid, flexible, and translucent options

Customer Ratings

Rating: 4.9 out of 5 (Based on verified reviews)

Customer Feedback

Incredible material flexibility and detail

Produces lifelike dental models

Clean prints with minimal post-processing

Game-changer for multi-material prototyping

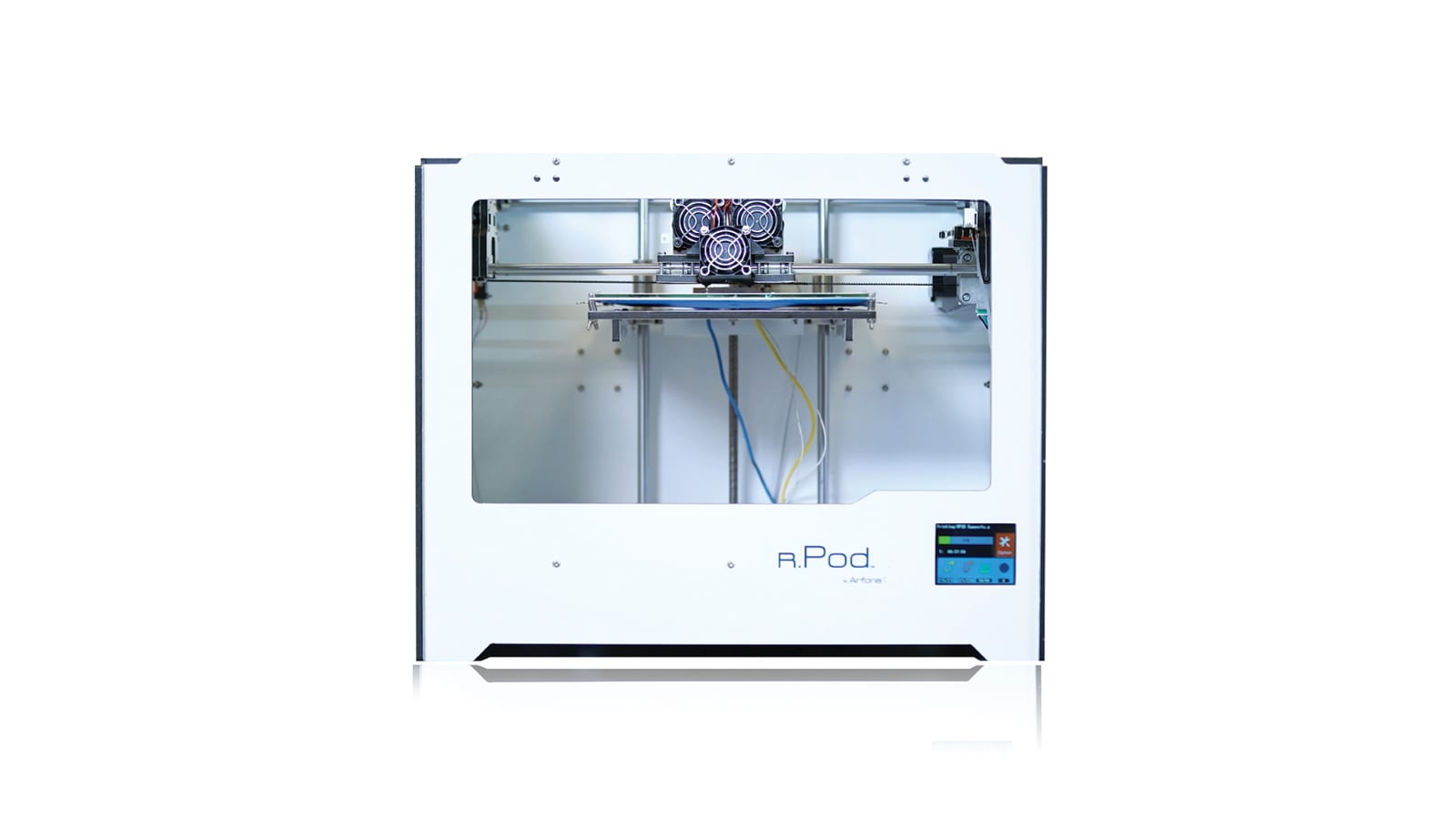

4. R. Pod by Arfona

Product Description

The R. Pod by Arfona is a fused deposition modeling (FDM) 3D printer specifically designed for dental applications, particularly the production of Valplast flexible nylon partial dentures. It offers an economical alternative to traditional dental manufacturing by utilizing widely available and cost-effective plastic filaments.

Product Overview

Engineered to maximize accuracy while minimizing material costs, the R. Pod focuses on the efficient extrusion of layers to create smooth and functional dental appliances. Its compatibility with FDA-approved Valplast resin ensures clinical reliability and flexibility in dental prosthetic production, making it ideal for practices and labs seeking low-cost, high-output 3D printing.

Key Features

Uses fused deposition modeling (FDM) technology

Optimized for Valplast flexible nylon materials

Compatible with inexpensive, widely available plastic filaments

Produces smooth, high-quality partial dentures

Cost-effective solution for dental appliance manufacturing

Streamlined for dental-specific applications

Common Applications

Fabricating flexible partial dentures

Printing Valplast appliances

Reducing lab and material costs in dental workflows

Use in dental offices and on-site prosthetic labs

Technical Specifications

Manufacturer: Arfona

Product Type: Dental FDM 3D Printer

Technology: Fused Deposition Modeling (FDM)

Material Compatibility: Valplast and other filament-based resins

Material Focus: Cost-effective plastic filament extrusion

Application Focus: Partial dentures and flexible appliances

Customer Ratings

Rating: 4.6 out of 5 (Based on verified reviews)

Customer Feedback

Perfect for Valplast denture production

Saves significantly on material costs

Simple operation with consistent output

Excellent for small practices and labs

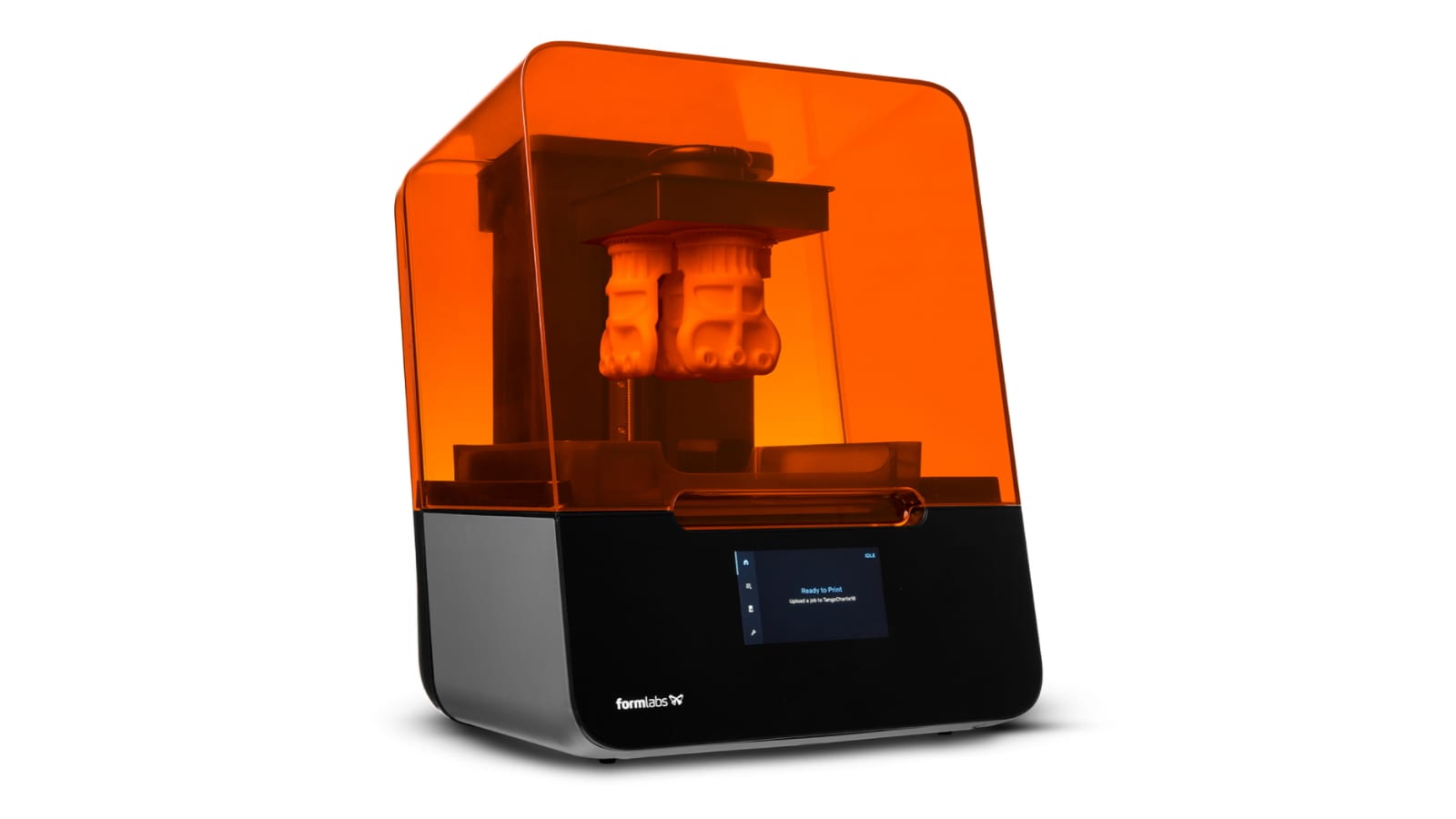

5. Form 3 by Formlabs

Product Description

The Form 3 by Formlabs is a next-generation dental 3D printer that utilizes Low Force Stereolithography (LFS) to improve surface quality, precision, and ease of post-processing. As the successor to the Form 2, it introduces advancements in laser power, XY resolution, and build reliability—ideal for producing dental models and appliances with high accuracy.

Product Overview

The Form 3 features a flexible film at the base of its resin tank to reduce peel forces, resulting in smoother surfaces and smaller support structures. Its Light Processing Unit (LPU) moves along the x-axis, delivering even exposure across the entire build plane. While some models may vary in build volume and resin compatibility, the Form 3 is optimized for clinics and labs focused on precision, efficiency, and repeatability.

Key Features

Low Force Stereolithography (LFS) for enhanced print quality

Improved laser strength and XY resolution

Flexible film base reduces peel forces and surface defects

Compact footprint with professional-grade reliability

Smaller, cleaner support structures simplify post-processing

Light Processing Unit travels on the x-axis for even exposure

Common Applications

Dental model production

Surgical guides, retainers, and splints

Clear aligners and diagnostic appliances

Use in dental offices and digital labs

Technical Specifications

Manufacturer: Formlabs

Product Type: LFS 3D Printer

Technology: Low Force Stereolithography (LFS)

Laser System: Precision LPU with XY-axis movement

Tank Base: Flexible film to minimize peel force

Resolution: Enhanced XY resolution compared to Form 2

Material Compatibility: Varies by Form 3 model

Customer Ratings

Rating: 4.8 out of 5 (Based on verified reviews)

Customer Feedback

Produces smooth, accurate dental models

Easy to use and clean

Great step up from the Form 2

Excellent reliability for small labs and practices