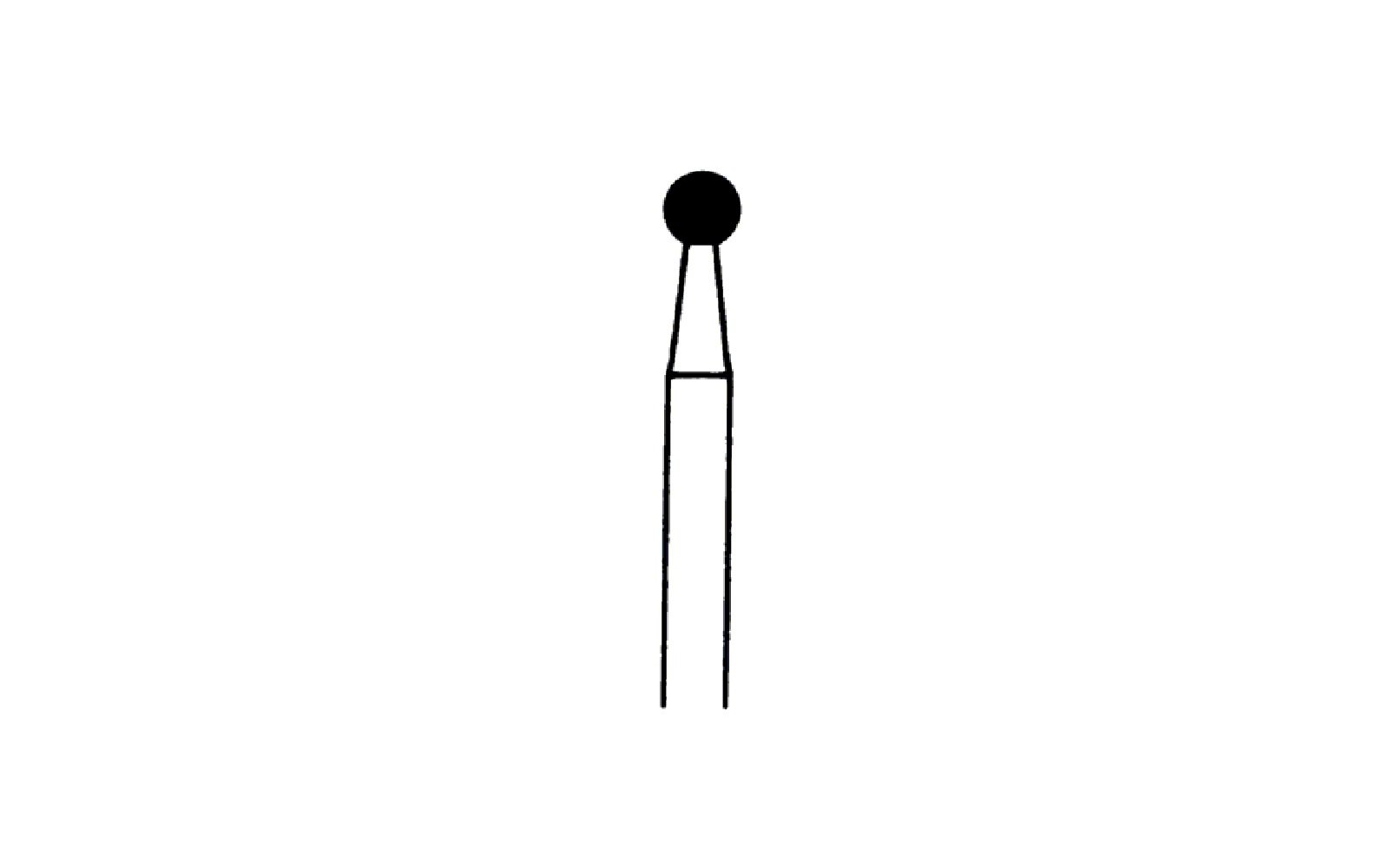

Diamond burs are used for precise drilling, finishing, and grinding where material removal is not a concern. Diamond burs produce cleaner cuts and a higher polish than carbide burs. When choosing a diamond bur, consider its grit. The diamond bur’s grit determines the speed and type of polish. Diamond burs with finer grits achieve a higher polish and finish, while those with coarser grits are suited for heavy material removal. Diamond burs are either standard or disposable. Standard diamond burs are reusable and should be sharpened and sterilized before use in another procedure. Disposable diamond burs are designed for single use and should not be reused in another procedure.

Comparison Table: Diamond Burs – Digits and Numbers

| Item Name | Grit | Type | Diameter (mm) | Length (mm) |

|---|---|---|---|---|

| Singles Dispo | Extra | Disposable | 1.600 | 3.500 |

| Spring Dispo | Extra | Disposable | 1.200 | 10.000 |

| Alpen x1 | Super | Single Use | 1.800 | 9.000 |

| Alpen Multi | Fine | Multi Use | 1.600 | 3.500 |

| Two Striper | Coarse | RA, Disposable | 1.200 | 4.000 |

| Diamond Inst | Medium | Multi Use | 2.700 | – |

| Singles Dispo | Coarse | Disposable | 1.200 | 8.000 |

| TDA Diamonds | Medium | Multi Use | 1.800 | – |

| Diamond Point | Coarse | HP, Single Use | 2.350 | – |

| Diamon-All | Coarse | Premium | – | – |

Comparison Table: Diamond Burs – Important Features

| Item Name | Sterilization | Material | Color Code | Manufacturing Place |

|---|---|---|---|---|

| Singles Dispo | Yes | Synthetic | Yes | – |

| Spring Dispo | – | Synthetic | – | USA |

| Alpen x1 | Gamma | Natural | – | – |

| Alpen Multi | – | Natural | – | – |

| Two Striper | – | Natural | – | – |

| Diamond Inst | – | Natural | – | – |

| Singles Dispo | Yes | Synthetic | Yes | – |

| TDA Diamonds | – | – | – | – |

| Diamond Point | – | – | – | USA |

| Diamon-All | – | Industrial | – | – |

Top 10 Dental Diamond Bur Sets

1. Patterson Singles Disposable Football Diamonds

Product Description

Patterson Singles Disposable Football Diamonds are individually packaged and pre-sterilized, eliminating the need for time-consuming sterilization before use. Designed for precision and efficiency, these disposable diamond burs ensure high-quality cutting performance with every application.

Product Overview

- Individually packaged and sterilized for immediate use

- Synthetic diamond grain for efficient and precise ablation

- Color-coded system for quick identification of proper grain size

- Designed for single-use to maintain optimal sharpness and hygiene

Key Features

High-Quality Cutting Performance – Synthetic diamond grain provides smooth and precise ablation

Pre-Sterilized Convenience – Ready-to-use, eliminating the need for sterilization

Color-Coded System – Quick visual identification of grain size for efficiency

Hygienic and Disposable – Single-use design ensures a fresh, sharp instrument each time

Common Applications

- Precision cutting and contouring in dental procedures

- Effective removal of enamel and restorative materials

- Use in cosmetic and restorative dentistry

Technical Specifications

- Brand: Patterson

- Type: Football Diamond Bur

- Material: Synthetic Diamond Grain

- Sterilization: Pre-Sterilized, Single-Use

- Color Coding: Extra Fine (Yellow)

- Diameter: 1.600 mm

- Length: 3.500 mm

- Package Quantity: 25/Pkg

Customer Ratings

Rating: 4.8 out of 5 (Based on verified reviews)

Customer Feedback

- Provides excellent precision and cutting performance

- Ready-to-use, saving time on sterilization

- Convenient color-coding for easy grain size selection

- Sharp and effective for single-use applications

Top 10 Dental Diamond Bur Holders for Dental Offices

2. Spring Diamonds Disposable

Product Description

Spring Health Products has been manufacturing high-quality diamond burs for over 30 years. The award-winning Spring FG Turbo & Regular Diamonds utilize an advanced electro-galvanizing process to bond the diamonds, ensuring superior cutting efficiency and durability. The precision-engineered shank and spiral design enhance performance by reducing turbine wear and heat buildup while providing a smooth, fast cut.

Product Overview

- Electro-galvanized diamond bonding for enhanced durability

- True concentricity with micro-precise shank calibration for a chatter-free experience

- Spiral design allows water to cool through diamond-free channels, preventing clogging

- Reduces chair time with faster, more efficient cutting performance

- Manufactured in the USA for quality assurance

Key Features

Fast & Efficient Cutting – Reduces chair time by optimizing the cutting speed for restorations

Clog-Free Performance – Spiral design prevents debris buildup and enhances cooling

Heat Reduction – Natural diamonds and precise placement minimize heat generation

Precision Engineering – Micro-calibrated shank diameters ensure a secure fit and smooth operation

Extended Turbine Life – Reduces wear on the turbine for long-term handpiece performance

Common Applications

- Efficient tooth preparation for restorations

- Cosmetic and restorative dentistry procedures

- Precision cutting with minimal heat buildup

Technical Specifications

- Brand: Spring Health Products

- Type: FG Turbo & Regular Diamonds

- Material: Electro-Galvanized Natural Diamonds

- Shank: 420 Heat-Treated Stainless Steel

- Manufactured In: USA

Customer Ratings

Rating: 4.9 out of 5 (Based on verified reviews)

Customer Feedback

- Provides a fast and smooth cutting experience

- Reduces clogging and overheating during use

- Secure and stable fit in the handpiece for precise control

- High-quality construction ensures long-lasting performance

3. Alpen® x1 Single Use Diamond Burs

Product Description

Alpen® x1 diamond burs are premium single-use instruments designed to provide Swiss precision and efficiency while minimizing the risk of cross-contamination. Each bur is individually wrapped and gamma-sterilized, ensuring optimal hygiene and safety for dental procedures.

Product Overview

- Single-use design for enhanced infection control

- Individually wrapped and gamma-sterilized for immediate use

- Coated with natural diamonds for superior cutting efficiency

- Standard friction grip (FG) shank for universal compatibility

Key Features

Swiss Precision – Manufactured with high-quality standards for consistent performance

Hygienic & Safe – Pre-sterilized and individually wrapped to prevent cross-contamination

Efficient Cutting – Uniform natural diamond coating ensures precise cutting and reduced chair time

Standard Compatibility – FG shank fits most high-speed handpieces for seamless operation

Common Applications

- Tooth preparation for crowns and bridges

- Fine finishing of enamel and restorations

- Use in cosmetic and restorative dental procedures

Technical Specifications

- Brand: Alpen®

- Type: Single-Use Diamond Bur

- Material: Natural Diamond Coating

- Sterilization: Gamma-Sterilized, Individually Wrapped

- Shank Type: Friction Grip (FG) Standard Length

- Package Quantity: 25/Pkg

Customer Ratings

Rating: 4.9 out of 5 (Based on verified reviews)

Customer Feedback

- Provides excellent precision with smooth cutting performance

- Convenient single-use design eliminates the need for sterilization

- Consistent quality and durability for professional dental work

- Secure fit in handpieces, reducing vibrations and improving accuracy

4. Alpen® Multi-Use Diamond Burs

Product Description

Alpen® Multi-Use Diamond Burs are engineered with precision using only natural diamonds to deliver superior cutting efficiency and extended instrument life. Featuring a Swiss Gold Diamond multi-layer application, these burs provide uniform crystal coverage for rapid, smooth, and comfortable cutting.

Product Overview

- Made with natural diamonds for optimal cutting performance

- Multi-layer diamond application ensures uniform crystal coverage

- Enhanced durability for extended instrument life

- Friction grip (FG) standard-length shank for universal compatibility

- Designed for rapid, smooth, and precise cutting

Key Features

Superior Cutting Performance – Natural diamond construction delivers enhanced cutting efficiency

Extended Durability – Multi-layer diamond application increases longevity

Smooth & Precise Cutting – Uniform crystal coverage ensures a comfortable cutting experience

Friction Grip (FG) Shank – Standard-length design for compatibility with high-speed handpieces

Common Applications

- Tooth preparation for crowns, bridges, and restorative procedures

- Efficient enamel shaping and finishing

- General cutting and contouring in cosmetic and restorative dentistry

Technical Specifications

- Brand: Alpen®

- Type: Multi-Use Diamond Bur

- Material: Natural Diamond Coating

- Application: Multi-Level Diamond Coverage

- Shank Type: Friction Grip (FG) Standard Length

- Durability: Reusable

Customer Ratings

Rating: 4.9 out of 5 (Based on verified reviews)

Customer Feedback

- Delivers fast, smooth, and precise cutting

- Long-lasting durability compared to other diamond burs

- Secure and stable fit in handpieces for enhanced control

- Provides a comfortable cutting experience with minimal chatter

5. Two Striper® Endo Diamond Burs

Product Description

Two Striper® Endo Diamond Burs feature P.B.S.® bonding technology, ensuring maximum exposure of diamond cutting surfaces for superior cutting efficiency. Designed with precisely placed diamond crystals, these burs provide durability and reliability for endodontic and restorative procedures. The high-quality diamond bonding guarantees longevity, preventing stripping or peeling while maintaining sharpness throughout use.

Product Overview

- P.B.S.® bonding technology for enhanced cutting performance

- Uniformly placed diamond crystals ensure precision and durability

- Permanently fused to a surgical-grade stainless steel shank

- Designed for effective grinding and preparation of tooth surfaces

- Guaranteed not to strip or peel, ensuring consistent performance

Key Features

Superior Cutting Efficiency – P.B.S.® bonding maximizes exposure of cutting surfaces

Long-Lasting Durability – Diamond crystals are permanently fused for extended use

Enhanced Precision – Uniform matrix placement ensures consistent and reliable cutting

Guaranteed Strength – Won’t strip or peel, maintaining integrity during procedures

Common Applications

- Tooth surface reduction and preparation for restorations

- Endodontic procedures requiring precision cutting

- Efficient removal of enamel and restorative materials

Technical Specifications

- Brand: Two Striper®

- Type: Endo Diamond Bur

- Material: P.B.S.® Bonded Natural Diamonds

- Shank Type: Surgical-Grade Stainless Steel

- Durability: Guaranteed not to strip or peel

Customer Ratings

Rating: 4.9 out of 5 (Based on verified reviews)

Customer Feedback

- Cuts faster and lasts longer compared to other burs

- Provides a smooth, precise cutting experience

- Strong and durable, with no risk of diamond stripping

- High-quality bonding ensures consistent performance in every use

6. Diamond Instruments, HP

Product Description

MEISINGER Diamond Rotary Instruments are designed for a wide range of preparation and finishing procedures involving composite, ceramic, and metal materials. Manufactured with natural diamonds, these instruments provide superior cutting efficiency and durability compared to synthetic alternatives. The hardened stainless steel profile body ensures precision and longevity, making them a reliable choice for dental professionals.

Product Overview

- Made with natural diamonds for superior cutting performance

- Hardened stainless steel profile body for enhanced durability

- Designed for use with composite, ceramic, and metal materials

- High precision and longevity for various dental applications

Key Features

Superior Cutting Efficiency – Natural diamonds ensure sharpness and longevity

Durable Construction – Hardened stainless steel shank and profile body for extended use

Versatile Application – Suitable for composite, ceramic, and metal finishing procedures

Precision Performance – Designed for smooth and efficient material removal

Common Applications

- Tooth preparation for composite and ceramic restorations

- Smoothing and contouring of dental materials

- Finishing procedures for enhanced restorative work

Technical Specifications

- Brand: MEISINGER

- Type: Diamond Rotary Instruments

- Material: Natural Diamond Coating, Stainless Steel Body

- Compatibility: Composite, Ceramic, and Metal Materials

- Durability: Long-lasting precision performance

Customer Ratings

Rating: 4.8 out of 5 (Based on verified reviews)

Customer Feedback

- Provides a smooth, precise cutting experience

- Highly durable with long-lasting performance

- Works efficiently with various restorative materials

- Natural diamonds offer superior results compared to synthetic alternatives

7. Singles Disposable Diamonds

Product Description

Singles Disposable Diamonds are individually packaged and pre-sterilized, eliminating the need for additional sterilization before use. Designed for efficiency and precision, these single-use diamond burs ensure optimal cutting performance while reducing cross-contamination risks.

Product Overview

- Individually packaged and sterilized for immediate use

- Synthetic diamond grain for efficient and precise ablation

- Color-coded system for quick identification of grain size

- Designed for single-use to maintain sharpness and hygiene

Key Features

Pre-Sterilized for Convenience – Ready to use with no additional sterilization required

Efficient Cutting Performance – Synthetic diamond grain ensures smooth and precise ablation

Color-Coded System – Quick visual identification of the proper grain size for various procedures

Hygienic & Single-Use – Reduces the risk of cross-contamination and maintains instrument sharpness

Common Applications

- Precision cutting and contouring in restorative dentistry

- Effective removal of enamel and restorative materials

- Use in cosmetic and general dental procedures

Technical Specifications

- Brand: Singles Disposable Diamonds

- Type: Disposable Diamond Bur

- Material: Synthetic Diamond Grain

- Sterilization: Individually Packaged & Pre-Sterilized

- Color Coding: Identifies grain size for quick selection

- Reusability: Single-Use

Customer Ratings

Rating: 4.8 out of 5 (Based on verified reviews)

Customer Feedback

- Provides excellent precision with sharp cutting performance

- Eliminates the need for time-consuming sterilization

- Easy to identify proper grain size with color-coding

- Reliable and hygienic for single-use applications

8. TDA Diamonds

Product Description

TDA® (Turbo Double Action) Diamond Burs feature an innovative cross-channel design that enhances cooling by creating a spray to dissipate heat buildup and remove debris. Designed for efficiency and durability, these burs use medium grit diamonds to minimize the need for additional finishing, while a three-layer matrix ensures an extended service life.

Product Overview

- Unique cross-channel design for improved cooling and debris removal

- Medium grit diamonds reduce the need for extensive finishing

- Three-layer diamond matrix extends the longevity of the bur

- Provides smooth and precise cutting performance

Key Features

Advanced Cooling System – Cross-channel design reduces heat buildup and prevents clogging

Efficient Cutting – Medium grit diamonds offer smooth and accurate material removal

Durable Construction – Three-layer diamond matrix enhances longevity and performance

Minimal Finishing Required – Leaves a smooth surface, reducing additional polishing steps

Common Applications

- Tooth preparation for restorative and cosmetic procedures

- Smoothing and contouring enamel and restorative materials

- Efficient material removal with minimal finishing required

Technical Specifications

- Brand: TDA® (Turbo Double Action)

- Type: Diamond Bur

- Material: Medium Grit Diamond Coating

- Cooling System: Cross-Channel Spray Design

- Durability: Three-Layer Diamond Matrix for Extended Use

Customer Ratings

Rating: 4.8 out of 5 (Based on verified reviews)

Customer Feedback

- Provides excellent cooling and reduces heat buildup

- Long-lasting durability with the three-layer diamond matrix

- Smooth cutting performance requiring minimal additional finishing

- Reliable and efficient for a wide range of dental procedures

9. Diamond Point Uncoated Burs

Product Description

Diamond Point Uncoated Burs are precision-plated diamond burs available in fine and coarse grits, designed for a wide range of dental and laboratory applications. Featuring a 3/32″ (2.35 mm) shank, these burs provide excellent control and durability. Manufactured in the USA, they meet high-quality standards for precision and efficiency.

Product Overview

- Available in fine and coarse grits for versatile applications

- Precision-plated design ensures consistent cutting performance

- 3/32″ (2.35 mm) shank for secure handpiece compatibility

- Manufactured in the USA for quality assurance

Key Features

Precision Cutting – Designed for fine and coarse grit applications

Uncoated for Specific Use Cases – Ideal for specialized finishing and shaping procedures

Durable Construction – High-quality plating ensures long-lasting performance

Standard Shank Size – 3/32″ (2.35 mm) shank fits compatible handpieces securely

Common Applications

- Fine finishing and shaping of dental materials

- Use in dental and laboratory settings for precision work

- Effective material removal in various restorative and cosmetic procedures

Technical Specifications

- Brand: Diamond Point

- Type: Uncoated Diamond Bur

- Grit Options: Fine and Coarse

- Shank Size: 3/32″ (2.35 mm)

- Manufactured In: USA

Customer Ratings

Rating: 4.7 out of 5 (Based on verified reviews)

Customer Feedback

- Provides excellent precision for both fine and coarse applications

- Uncoated design allows for versatile use

- Secure fit in handpieces for smooth operation

- High-quality craftsmanship ensures long-lasting durability

10. Diamon-All® Premium Cutting Instruments

Product Description

Diamon-All® is a patented, fine-cutting diamond instrument engineered for precision and versatility. Constructed from uniform-sized industrial diamonds bonded with a noncontaminating, nonmetallic organic binder, this cutting instrument ensures smooth and aggressive performance. Its innovative design allows for seamless use on both metal and porcelain without the risk of cross-contamination. Additionally, each use creates a new cutting surface, preventing clogging and enhancing efficiency.

Product Overview

- Fast-cutting yet smooth performance for various dental materials

- Nonmetallic binder eliminates the risk of contamination between metal and porcelain

- Self-renewing cutting surface prevents clogging and maintains efficiency

- Available in Fine, Medium, and Coarse grits for different applications

- Designed in 7 distinct shapes to accommodate various cutting needs

Key Features

Cross-Contamination Prevention – Nonmetallic binder allows for interchangeable use on metal and porcelain

Self-Renewing Cutting Surface – Each use reveals a fresh cutting surface, reducing clogging

Versatile Application – Suitable for finishing alloys, ceramic materials, composites, and other dental materials

Smooth & Efficient Cutting – Provides aggressive yet controlled cutting performance

Wide Range of Shapes & Grits – Available in 7 shapes and Fine, Medium, and Coarse grits

Common Applications

- Finishing and contouring ceramic, composite, and metal dental materials

- Precision shaping of restorations and dental prosthetics

- Effective cutting without chipping or overheating porcelain

Technical Specifications

- Brand: Diamon-All®

- Type: Premium Diamond Cutting Instrument

- Material: Industrial Diamonds with Nonmetallic Organic Binder

- Grit Options: Fine, Medium, and Coarse

- Available Shapes: Pencil, Tapered Pencil, Barrel, Inverted Cone, Wheel, Small Wheel, Tapered Small Wheel

- Application: Metal, Porcelain, and Composite Finishing

Customer Ratings

Rating: 4.9 out of 5 (Based on verified reviews)

Customer Feedback

- Excellent cutting precision with smooth results

- No overheating or chipping when working on porcelain

- Eliminates cross-contamination concerns between metal and ceramic materials

- Long-lasting durability with a self-renewing cutting surface