A simple guide to selecting a CAD/CAM milling machine

CAD/CAM milling machines have only developed over the past few years, but today’s dental laboratories now feature various milling options. Even while the inner hardware of milling machines hasn’t changed, the dynamics of what they offer have and thus can make it difficult for dentists to choose features that will best support their practices. Tooling and milling strategies matter when choosing the right milling machine for your practice, but so does the machine itself. With the accuracy of today’s fabrication process, dental object printing has become a more potent, reliable source for restorations.

The Evolution of CAD/CAM Machines

CAD/CAM machines were originally developed in the 1960s for the aircraft and automobile industries. Still, it wasn’t until 1971 when Dr. Francosis Duret developed the first CAD/CAM machine for an abutment tooth and produced the first restoration for treatment in 1983. These CAD/CAM machines didn’t have digitization scanners and had to be manually operated to produce dental crowns, veneers, and other restorations. It wasn’t until 1987 when Mörmann and Brandestini discovered the CEREC system, which combined digital scanning with a milling unit to produce dental restorations.

All CAD/CAM machines contain three essential components:

Computerized Surface Scanners – Also referred to as the machine’s software, all geometric shapes are transformed into digital data using multiple scanning and digitization methods. The data acquired to transmute the information into a physical impression can be done through the following:

Optical Scanners – These types of scanners consist of a collection of three-dimensional structures operating in a triangulation procedure. The laser, acting as the light source, and the receptor are positioned at a definite angle to calculate a three-dimensional data set for the image. Some examples of these kinds of CAD/CAM machines are the ES1 and 3M ESPE Lava Scan ST.

Mechanical Scanners – Mechanical scanners use a master cast and ruby ball that reads mechanically line-by-line to create the three-dimensional structure. The diameter of the rubber ball is set to the smallest grinder in the milling system and produces a high scanning accuracy, milling all the data collected. However, mechanical scanners are more expensive, have more complicated mechanics, and have a longer processing time.

Design Software – The number of milling axes within the machine distinguishes the design software. The number of milling axes determines the degree of movement during the design process of the restoration and how many adjustments can be made during design.

3-axis milling – These milling machines operate in three spatial directions and are defined by the X-, Y-, and Z- values. These devices can turn the component by 180 degrees when processing the inside and outside of the data image. These machines produce shorter milling times, have more simplified controls, and are cost-effective.

4-axis milling – A 4-axis milling machine includes the three spatial axes and a tension bridge for turning infinitely. This gives the construction a larger vertical height displacement to save materials and milling time for creating mold dimensions.

5-axis milling – In addition to the three spatial axes and tension bridge, a milling spindle enables the milling of complex geometries within subsections of the mold design.

When it comes to processing methods for CAD/CAM systems, two classifications of milling processing determine the materials needed for the milling machine and the costs, including:

Dry Processing: Also called dry grinding or dry ball milling, dry milling uses pressurized air and a vacuum to remove material particles. Dry milling can use materials such as zirconia, polyester ether ketone, PMMA, and wax to develop prosthetics and restorations.

Wet Processing: A spray of cool liquid protects the milling diamond or carbide cutter to avoid damage due to heat. This process is necessary for metals, ceramics, and resins and typically produces a less grain-filled and more accurate restoration.

Depending on the company, each system has its own specifications and operating systems for milling machines. So, when searching for a wet or dry milling machine, please pay attention to what their digitization scanners operate on matters. Here are our suggestions for the top milling machines, their prices, and brief specifications on what they offer for your practice.

Ultimate Guide to Planmeca PlanMill 40 S Review

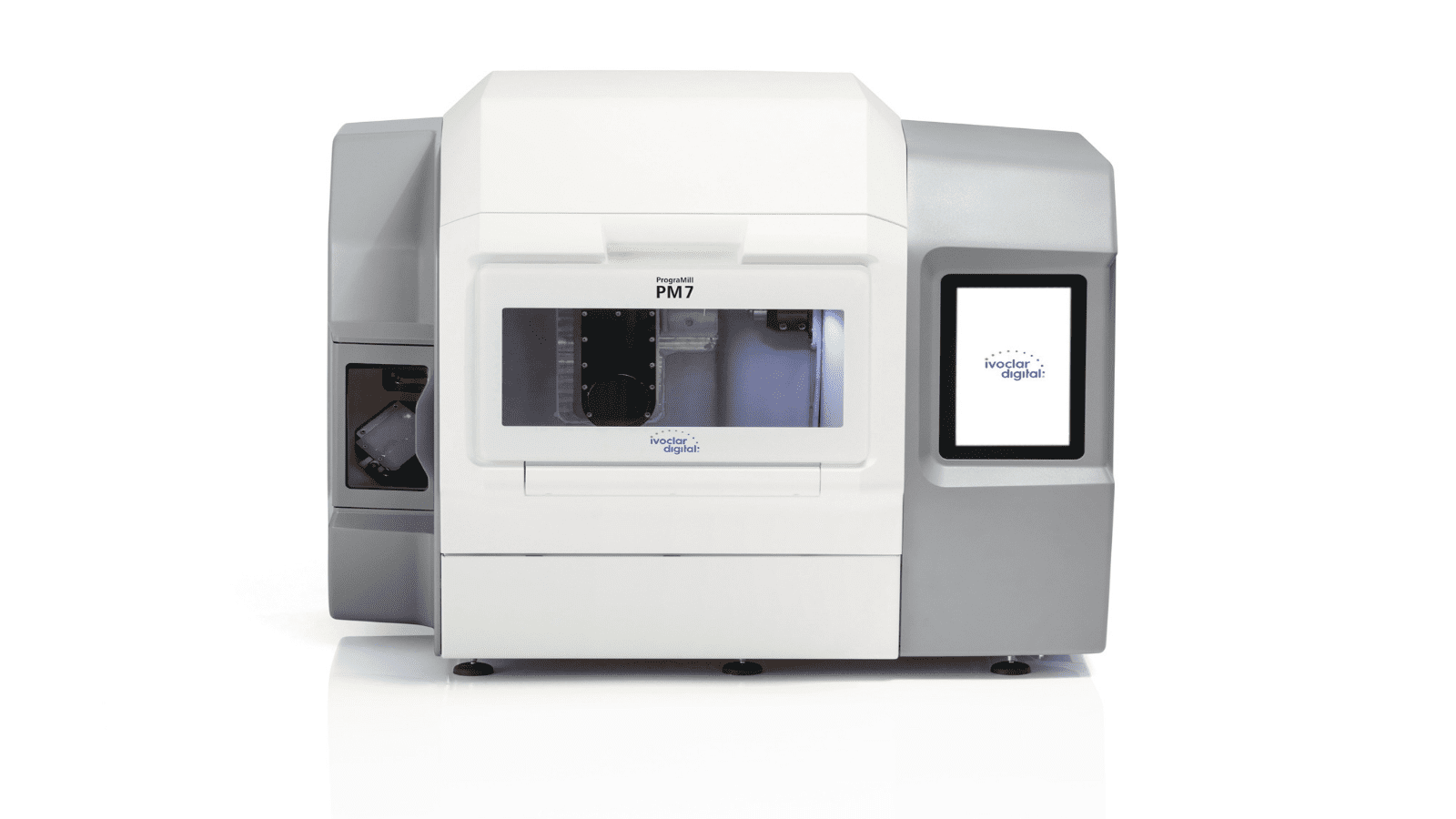

1. PrograMill PM7 by Ivoclar Vivadent

Product Description

The PrograMill PM7 is a powerful 5-axis milling unit designed for both dry and wet processing. Its hybrid capabilities, integrated touchscreen interface, and intelligent automation make it an advanced solution for efficient, high-quality dental restorations.

Product Overview

Built for speed and precision, the PrograMill PM7 offers seamless fabrication through centralized control. It features synchronized material and tool changers, an internal PC with a user-friendly touchscreen, and an ionizer to minimize cleaning during PMMA processing. Its compatibility with a wide range of materials—including lithium disilicate and zirconia—makes it suitable for a variety of clinical and laboratory applications.

Key Features

- 5-axis simultaneous milling for complex geometries

- Integrated PC with touchscreen monitor

- Dry and wet material compatibility

- Automatic tool and material changers for continuous workflow

- Centralized control system for optimized milling strategies

- Built-in ionizer reduces PMMA dust buildup and cleaning time

- High-performance 970-watt spindle with servomotors

- Supports lithium disilicate, PMMA, zirconia, and more

Common Applications

- Milling of inlays, onlays, crowns, bridges

- Frameworks and full-contour restorations

- Provisional and long-term prosthetics

- Implant-supported structures

- CAD/CAM-based design and production workflows

Technical Specifications

- Power Output: 970 watts

- Axis Movement: 5-axis

- Processing: Wet and dry

- Interface: Integrated touchscreen PC

- Automation: Automatic tool/material changers

- Additional Feature: Built-in ionizer for PMMA dust reduction

Customer Feedback

Users report excellent precision, reduced manual intervention, and smoother workflows. Many highlight its ability to handle diverse material types and complex cases with ease, making it a valuable asset in high-demand environments.

More Information

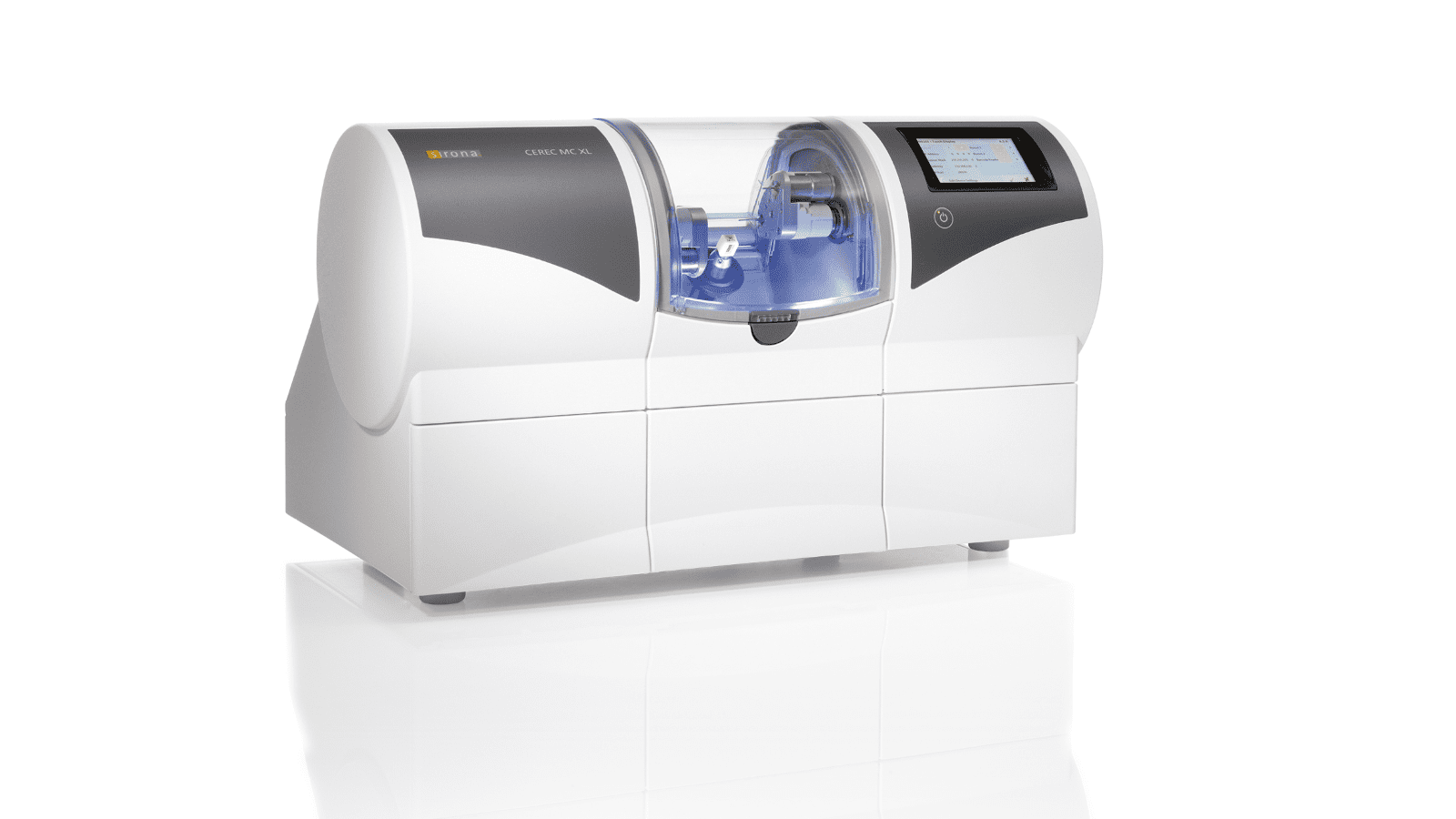

2. CEREC MC XL by Dentsply Sirona

Product Description

The CEREC MC XL is a high-performance chairside milling unit designed to produce a wide range of dental restorations with precision and efficiency. Its advanced technology enables dental professionals to fabricate restorations in a single visit, enhancing patient satisfaction and practice productivity.

Product Overview

Equipped with four spindle motors, the CEREC MC XL can mill and grind various materials, including ceramics and composites. It supports the fabrication of inlays, onlays, crowns, veneers, bridges, abutments, and surgical guides. The unit’s intuitive touchscreen interface allows for easy operation and monitoring of the milling process.

Key Features

- Four spindle motors for efficient milling and grinding

- Compatible with a variety of materials, including ceramics and composites

- Supports a wide range of restorations: inlays, onlays, crowns, veneers, bridges, abutments, and surgical guides

- Intuitive touchscreen interface for easy operation

- Fast milling times, with crowns produced in approximately 10 minutes

- Integrated with CEREC software for seamless workflow

Common Applications

- Single-visit restorations

- Fabrication of crowns, inlays, onlays, and veneers

- Production of bridges and implant abutments

- Creation of surgical guides for implant procedures

Technical Specifications

- Dimensions: 42 x 70 x 40 cm (16.53 x 27.56 x 15.75 inches)

- Weight: 43 kg (95 pounds)

- Power Requirements: 100V-230V, 50/60 Hz, 1.5 – 3.5 A

- Milling Time: Approximately 10 minutes per unit

- Material Block Size: Up to 85 x 40 x 22 mm

- Number of Axes: 4

- Automatic Tool Changing: No

- Wet Grinding: Not supported

Customer Ratings

Highly regarded for its speed, precision, and versatility, the CEREC MC XL is a popular choice among dental professionals seeking to enhance their practice’s capabilities.

Customer Feedback

Users appreciate the unit’s ability to produce high-quality restorations quickly, reducing the need for multiple patient visits. The intuitive interface and seamless integration with CEREC software contribute to an efficient and user-friendly experience.

3. Planmeca PlanMill 30S by Planmeca

Product Description

The Planmeca PlanMill 30S is a high-precision, chairside milling unit designed for efficient, same-day dental restorations. With a powerful single-spindle motor and a 4-axis milling system, it offers excellent performance across a wide range of materials and restoration types.

Product Overview

Built for speed and reliability, the PlanMill 30S operates at up to 100,000 RPM and uses linear motor technology for precise rotary axis control. The unit features a five-position tool changer and an open platform design, allowing seamless integration with most dental systems. Its average milling time of 20–25 minutes makes it well-suited for both single-unit and complex restorations.

Key Features

- Single-spindle motor with 4-axis simultaneous milling

- High-speed performance with up to 100,000 RPM

- Linear motor-driven rotary axis for precise control

- Five-position automatic tool changer

- Open platform for easy integration with third-party systems

- Supports multiple material types: ceramic, composite, abutment blocks

- Efficient milling time of 20–25 minutes

- Designed for smooth chairside operation

Common Applications

- Single and multi-unit crowns

- Inlays, onlays, and veneers

- Abutment and implant restorations

- Aesthetic composite restorations

- Custom-fit milling for various case types

Technical Specifications

- Spindle Speed: Up to 100,000 RPM

- Axes: 4-axis system

- Tool Positions: 5

- Milling Time: 20–25 minutes per restoration

- Platform: Open system

- Compatible Materials: Ceramic, composite, abutment materials

Customer Ratings

Well-reviewed for its accuracy, system flexibility, and ease of use in high-demand practices offering same-day restorations.

Customer Feedback

Dentists value the machine’s open integration and ability to work with a wide range of restorative materials. Its speed, precision, and reliability are frequently mentioned as top strengths for busy clinical environments.

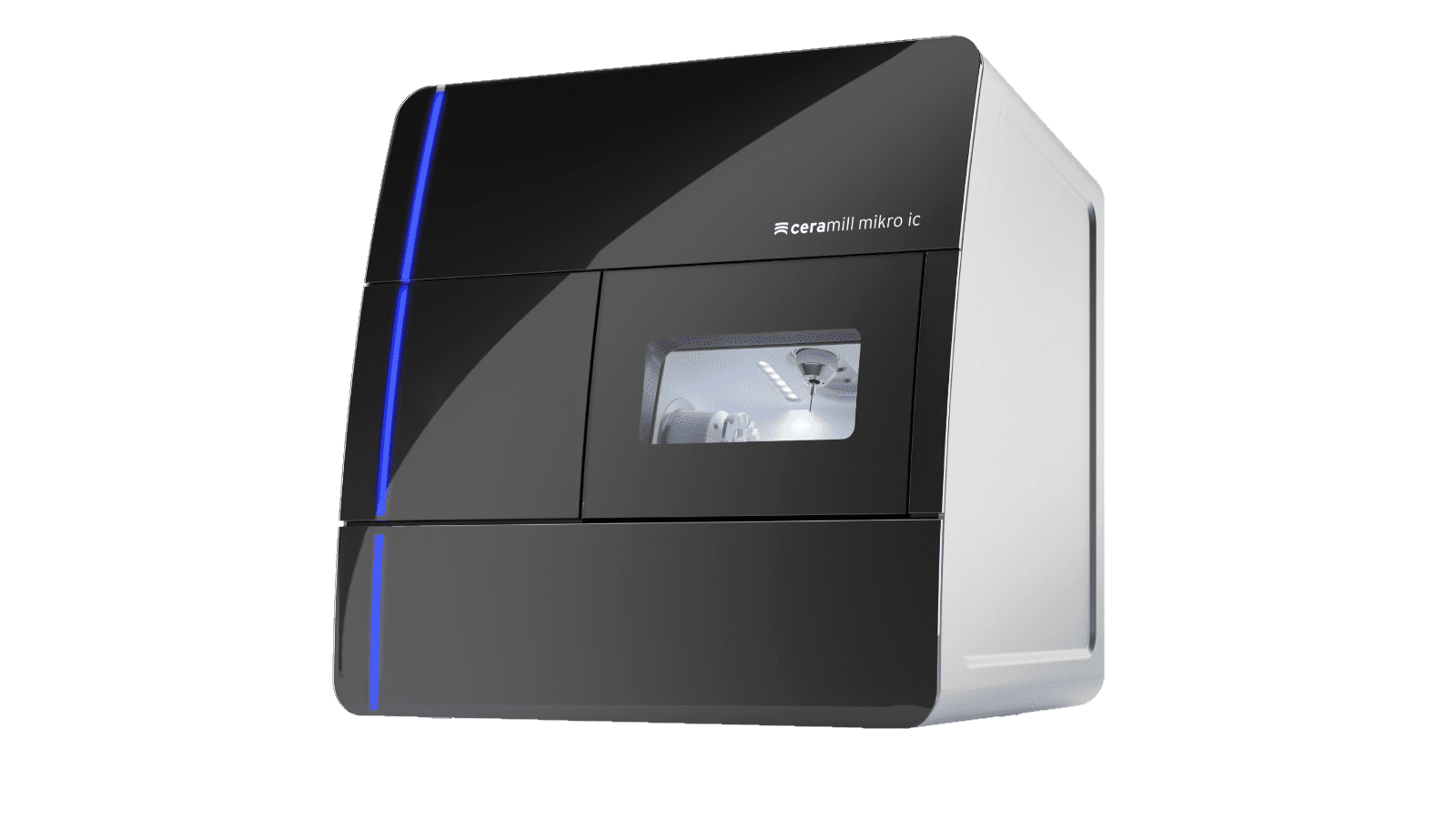

4. Ceramill Mikro IC by Amann Girrbach

Product Description

The Ceramill Mikro IC is a compact yet high-performance 4-axis milling unit designed for wet grinding of complex dental restorations. Engineered with advanced DNA milling strategies, it delivers exceptional precision and durability, making it ideal for handling demanding materials like glass ceramics and titanium.

Product Overview

Optimized for speed and accuracy, the Ceramill Mikro IC features an 8-position automatic tool changer and a 750-watt motor. It includes a carving mode that reduces processing time by up to 60%, while its thrilling mode enables the precise adaptation of standard CAD blocks into block assemblies. Its sturdy build and wet processing capability ensure consistent results for both simple and advanced milling cases.

Key Features

- 4-axis wet milling with high precision and minimal vibration

- DNA milling strategies for efficient and accurate material removal

- 8-position automatic tool changer

- 750-watt motor for robust cutting performance

- Carving mode for up to 60% faster processing

- Thrilling mode for converting standard CAD blocks into assemblies

- Designed for hard materials like titanium and glass ceramics

- Compact, space-saving footprint with high reliability

Common Applications

- Inlays, onlays, and full-contour crowns

- Bridges and veneers

- Titanium and glass ceramic restorations

- Precision milling of complex prosthetic components

- Block adaptation for advanced restorative work

Technical Specifications

- Milling Type: Wet

- Axes: 4-axis system

- Power Output: 750 watts

- Tool Changer: 8-position automatic

- Carving Mode: Yes, up to 60% time reduction

- Thrilling Mode: Yes, for block assembly adaptation

- Compatible Materials: Titanium, glass ceramics, and other hard materials

Customer Ratings

Recognized for its compact power, milling speed, and ability to process high-strength materials with precision.

Customer Feedback

Users appreciate its advanced milling modes, easy material handling, and strong cutting capability. The carving and thrilling modes are especially praised for saving time and expanding restoration possibilities.

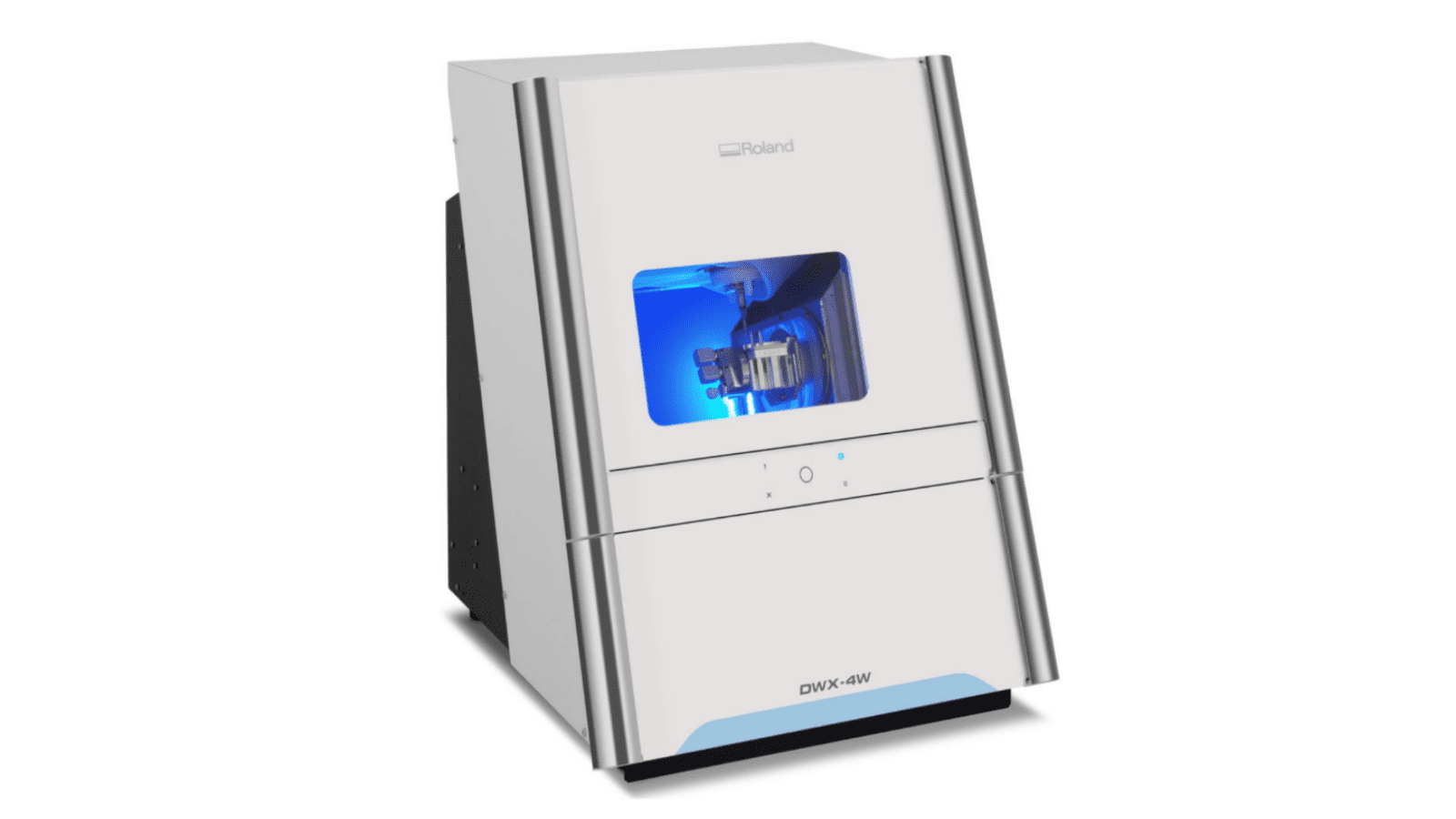

5. DWX-4W Wet Dental Mill – Roland

Product Description

The DWX-4W is a compact 4-axis wet milling machine engineered for high-precision fabrication of glass ceramic and composite resin restorations. Ideal for small labs or chairside use, it delivers consistent milling performance with user-friendly operation and minimal maintenance.

Product Overview

Built to handle daily restorative demands, the DWX-4W includes ball screw-driven control, multi-pin clamps for simultaneous milling, and an automatic tool changer. With a maximum spindle speed of 60,000 RPM, it efficiently produces crowns, inlays, and bridges while maintaining tight tolerances. The system supports one-button operation and can deliver restorations for up to three patients per day without interruption.

Key Features

- 4-axis wet milling for glass ceramics and composite resins

- Ball screw-driven axis for precision and durability

- Multi-pin clamp system for simultaneous milling

- Automatic tool changer for uninterrupted production

- One-button operation for ease of use

- High-speed spindle up to 60,000 RPM

- Compact and quiet design suitable for clinical environments

Common Applications

- Crowns and inlays

- Onlays and veneers

- Three-unit bridges

- Same-day restorations in ceramic and resin materials

Technical Specifications

- Milling Type: Wet

- Axes: 4-axis system

- Spindle Speed: Up to 60,000 RPM

- Tool Changer: Automatic

- Material Compatibility: Glass ceramic and composite resin

- Operation: One-button control

- Patient Capacity: Up to 3 patients/day without interruption

Customer Ratings

Appreciated for its precision, simplicity, and space-saving design, the DWX-4W is a top choice for smaller practices and labs focused on high-quality, in-house milling.

Customer Feedback

Users commend the DWX-4W for its reliability, intuitive operation, and the ability to produce multiple restorations in a single day. Its clean, quiet performance and consistent output make it a popular choice for chairside restorative workflows.