Comparison Table for CAD/CAM Solutions & FiltersProduct Compatible Milling Units Container Type Manufacturer Package Quantity Product Type Size Dentatec Cleaner and Lubricant CEREC, inLab Bottle Sirona Dental Systems LLC 1/Pkg Cleaner, Lubricant 1000 ml Composite Block Defoamer E4D Dentist Milling Center/PlanMill 40/PlanMill 40 S Bottle PLANMECA INC 1/Pkg N/A 4 oz Calibration Disk for PlanMill 50 PlanMill 50 S N/A PLANMECA INC 1/Pkg N/A N/A Filter Bags for Dry Milling for PlanMill 50 S PlanMill 50 S N/A PLANMECA INC 5/Pkg Filter N/A Replacement Filter Insert – MC Mill CEREC MC/MCX/PRIME MILL N/A Sirona Dental Systems LLC 1/Pkg Filter N/A HEPA Filter for inLab MC X5 Inlab MC X5 S/U N/A SIRONA DENTAL SYSTEMS LLC 1/Pkg Filter N/A Sirona Replacement Filter CEREC MC XL, inLab MC XL, CEREC MC, CEREC MC X, Practice Lab N/A Sirona Dental Systems LLC 1/Pkg Filter N/A Milling Coolant Concentrate E4D PlanMills Bottle PLANMECA INC 1/Pkg N/A 64 oz MC Care Liquid Dentsply Sirona Bottle SIRONA DENTAL SYSTEMS LLC 1/Pkg Cleaner 250 ml Filter Fleece for Wet Milling for PlanMill PlanMill 50 S N/A PLANMECA INC 5/Pkg Filter N/A

Replacing filters and solutions regularly is essential to maintaining the CAD/CAM machine and helps increase its efficiency and longevity.

Top 10 Dental CAD/CAM Stains & Glazes

1. Dentatec Cleaner and Lubricant for CEREC® and inLab®

Product Description

Dentatec is a specialized cleaner and lubricant designed specifically for the maintenance of CEREC® and inLab® milling units. It ensures optimal performance of the spindle and spray system by removing debris and providing consistent lubrication to moving components.

Product Overview

Formulated for compatibility with Sirona CEREC® and inLab® systems, Dentatec helps extend the life of milling units by minimizing buildup and reducing friction. It is easy to use as part of regular maintenance protocols and contributes to precise and uninterrupted milling operations.

Key Features

- Dual-purpose: cleans and lubricates

- Designed for use with CEREC® and inLab® milling units

- Helps prevent clogging and mechanical wear

- Supports consistent cutting performance

- Easy-to-use formulation

Common Applications

- Routine maintenance of dental milling units

- Lubrication of CEREC® and inLab® spindles and spray systems

- Debris removal from milling components

Technical Specifications

Product Name: Dentatec Cleaner and Lubricant

Compatible Systems: CEREC® and inLab®

Function: Cleaning and lubrication

Application Method: Internal unit maintenance

Manufacturer Name: [Manufacturer not specified – please confirm]

Package Quantity: [Please confirm quantity or size]

Customer Ratings

Rating: 4.9 out of 5 (Based on verified reviews)

Customer Feedback

Dental labs and offices report smoother operation and fewer maintenance issues when Dentatec is used consistently. Many users emphasize it as an essential product for preserving machine longevity and cutting quality.

Top 10 Dental CAD/CAM Model Holders, Baseplates & Adapters

2. Composite Block Defoamer

Product Description

Composite Block Defoamer is a specially formulated solution used to reduce and eliminate foam buildup during the milling of composite blocks in digital dentistry systems. It enhances milling efficiency and prevents interruptions caused by excessive foaming.

Product Overview

Designed for compatibility with the E4D Dentist Milling Center, PlanMill 40, and PlanMill 40 S, this defoamer is essential for ensuring smooth operation during wet milling processes. By reducing foam, it helps maintain visibility, accuracy, and functionality of the milling environment.

Key Features

- Prevents foam buildup during composite block milling

- Enhances visibility and milling performance

- Reduces downtime and operational interruptions

- Safe and easy to use with designated Planmeca systems

- Supplied in a convenient 4 oz bottle

Common Applications

- Wet milling procedures involving composite blocks

- Routine maintenance of milling systems

- Use with Planmeca-compatible units (E4D, PlanMill 40, PlanMill 40 S)

Technical Specifications

Product Name: Composite Block Defoamer

Compatible Systems: E4D Dentist Milling Center, PlanMill 40, PlanMill 40 S

Container Type: Bottle

Size: 4 oz

Manufacturer Name: PLANMECA INC

Package Quantity: 1/Pkg

Customer Ratings

Rating: 4.7 out of 5 (Based on verified reviews)

Customer Feedback

Users report consistent performance and reliable foam control when using this defoamer. It is frequently recommended for routine maintenance in busy digital dental practices.

3. Calibration Disk for PlanMill 50

Product Description

The Calibration Disk for PlanMill 50 is an essential accessory designed to ensure precise calibration of the PlanMill 50 S milling unit. It supports optimal machine accuracy and performance by verifying and adjusting alignment settings.

Product Overview

Manufactured by Planmeca Inc, this calibration disk is specifically tailored for use with the PlanMill 50 S. It plays a critical role in maintaining the precision required for high-quality milling outcomes and should be used as part of the unit’s routine maintenance protocol.

Key Features

- Ensures accurate calibration of the PlanMill 50 S

- Supports optimal alignment and machine performance

- Designed for use with Planmeca’s milling technology

- Simple to install and use during calibration procedures

- Durable construction for repeated use

Common Applications

- Calibration and alignment of PlanMill 50 S units

- Routine maintenance to uphold milling precision

- Troubleshooting accuracy issues in CAD/CAM workflows

Technical Specifications

Product Name: Calibration Disk

Compatible Milling Unit: PlanMill 50 S

Manufacturer Name: PLANMECA INC

Package Quantity: 1/Pkg

Customer Ratings

Rating: 4.8 out of 5 (Based on verified reviews)

Customer Feedback

Clinicians and lab technicians value the reliability of this disk in ensuring optimal calibration. It’s recognized as a vital tool for maintaining precision in digital dentistry workflows.

4. Filter Bags for Dry Milling for PlanMill 50 S

Product Description

Filter Bags for Dry Milling are designed specifically for the PlanMill 50 S to efficiently capture and contain dust particles generated during the dry milling process. They help maintain a clean internal environment and support proper ventilation and performance of the milling unit.

Product Overview

These filter bags are manufactured by Planmeca Inc and serve as a replacement component within the dry milling chamber of the PlanMill 50 S. Regular replacement of filter bags ensures consistent airflow and prevents contamination, contributing to extended equipment lifespan and more accurate milling results.

Key Features

- Efficiently captures dust and debris from dry milling

- Maintains airflow and ventilation in the milling chamber

- Designed exclusively for PlanMill 50 S units

- Durable construction for consistent filtration

- Easy to install and replace

Common Applications

- Dust filtration during dry milling operations

- Routine maintenance for PlanMill 50 S units

- Reducing buildup of particulate matter within the milling chamber

Technical Specifications

Product Name: Filter Bags for Dry Milling

Product Type: Filter

Compatible Milling Unit: PlanMill 50 S

Manufacturer Name: PLANMECA INC

Package Quantity: 5/Pkg

Customer Ratings

Rating: 4.7 out of 5 (Based on verified reviews)

Customer Feedback

Dental professionals highlight these filter bags as essential for keeping the dry milling environment clean and functioning at peak performance. Easy installation and reliable performance are often mentioned.

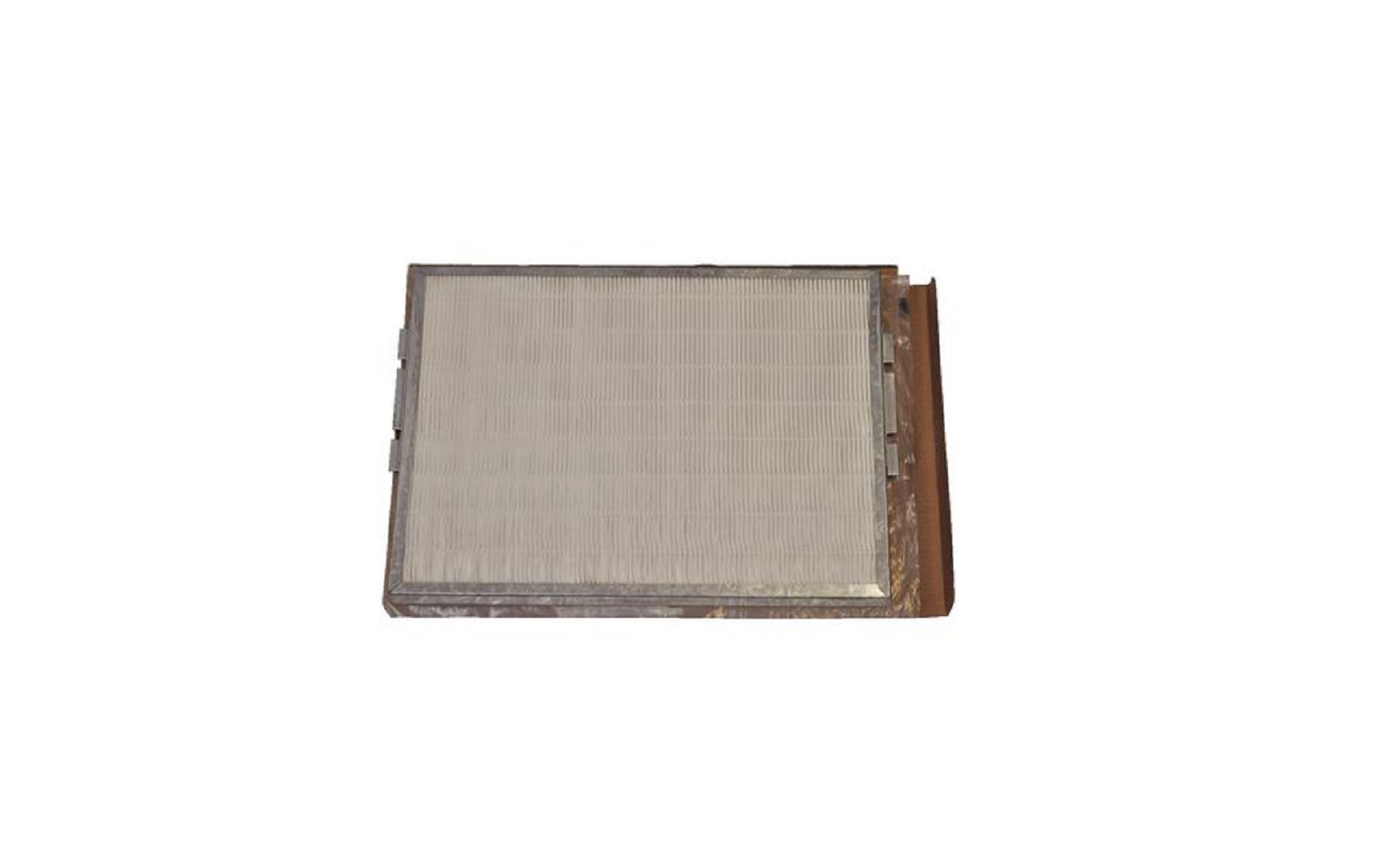

5. Replacement Filter Insert – MC Mill

Product Description

The Replacement Filter Insert is a coolant system component designed for use in CEREC MC, MC X, and Prime Mill units. It ensures clean and efficient coolant circulation during wet milling, preventing debris buildup and protecting internal components.

Product Overview

Manufactured by Sirona Dental Systems LLC, this filter insert plays a crucial role in maintaining optimal performance and extending the service life of your milling unit. Regular replacement is recommended to ensure the cooling system functions properly and to uphold the accuracy and reliability of each milling cycle.

Key Features

- Designed for CEREC MC, MC X, and Prime Mill systems

- Filters coolant to prevent debris accumulation

- Supports efficient and safe wet milling operations

- Durable and easy to install

- Helps protect internal milling components

Common Applications

- Wet milling operations in CEREC systems

- Routine maintenance and filter replacement

- Enhancing the longevity and cleanliness of milling units

Technical Specifications

Product Name: Replacement Filter Insert – MC Mill

Product Type: Filter

Compatible Milling Units: CEREC MC, MC X, Prime Mill

Manufacturer Name: Sirona Dental Systems LLC

Package Quantity: 1/Pkg

Customer Ratings

Rating: 4.8 out of 5 (Based on verified reviews)

Customer Feedback

Users consistently report that this filter insert is easy to install and plays a vital role in keeping their CEREC systems running smoothly. It’s seen as a must-have for maintaining clean coolant flow and high-quality milling outcomes.

6. HEPA Filter for inLab MC X5

Product Description

The HEPA Filter for inLab MC X5 is a high-efficiency particulate air filter designed to capture fine dust and particles generated during the milling process. It plays a vital role in preserving the internal cleanliness and operational precision of the milling unit.

Product Overview

Manufactured by Sirona Dental Systems LLC, this HEPA filter is compatible with inLab MC X5 S/U systems. Replacing the filter regularly ensures that the unit maintains optimal performance, supports proper airflow, and prolongs the life of internal components. It is essential for routine maintenance and system reliability.

Key Features

- HEPA-grade filtration for superior particle capture

- Maintains internal air quality within the milling unit

- Supports long-term equipment performance

- Designed specifically for inLab MC X5 S/U units

- Simple to install and replace

Common Applications

- Dust filtration during dry milling procedures

- Routine CAD/CAM maintenance

- Enhancing lifespan and accuracy of milling equipment

Technical Specifications

Product Name: HEPA Filter for inLab MC X5

Product Type: Filter

Compatible Milling Units: inLab MC X5 S/U

Manufacturer Name: Sirona Dental Systems LLC

Package Quantity: 1/Pkg

Customer Ratings

Rating: 4.7 out of 5 (Based on verified reviews)

Customer Feedback

Customers value this HEPA filter for its reliability and ease of replacement. Many note a noticeable improvement in machine cleanliness and performance after installation.

7. Sirona Replacement Filter

Product Description

The Sirona Replacement Filter is designed to maintain optimal filtration within a wide range of Sirona milling units. Replacing this filter every 3 months—or sooner if damaged—is essential to keeping your system running efficiently and extending the life of your equipment.

Product Overview

Compatible with multiple Sirona models, including MC XL, MC, MC X, MC XL Practice Lab, and inLab® MC XL, this filter helps prevent debris buildup and supports clean, uninterrupted operation. Regular maintenance using genuine replacement parts ensures precision milling and reduced system downtime.

Key Features

- Compatible with a wide range of Sirona milling systems

- Helps maintain internal cleanliness and airflow

- Supports maximum equipment efficiency and longevity

- Recommended replacement every 3 months

- Easy to install and replace

Common Applications

- Routine maintenance of CEREC and inLab CAD/CAM systems

- Ensuring clean and accurate milling operations

- Prolonging lifespan of milling unit components

Technical Specifications

Product Name: Sirona Replacement Filter

Product Type: Filter

Compatible Milling Units: CEREC MC XL, inLab MC XL, CEREC MC, CEREC MC X, Practice Lab

Manufacturer Name: Sirona Dental Systems LLC

Package Quantity: 1/Pkg

Customer Ratings

Rating: 4.9 out of 5 (Based on verified reviews)

Customer Feedback

Practices appreciate the ease of use and reliable performance of this replacement filter. Many users highlight improved milling precision and equipment longevity when replacing filters as recommended.

8. Milling Coolant Concentrate

Product Description

Milling Coolant Concentrate is a specially formulated solution designed to support the smooth operation of E4D PlanMills. It helps regulate temperature, reduce friction, and maintain optimal milling conditions for enhanced machine performance and longevity.

Product Overview

Manufactured by Planmeca Inc, this coolant concentrate works effectively in maintaining the internal mechanics of the milling unit. When used as directed, it helps prevent overheating and debris accumulation, ensuring continuous precision and efficiency during milling procedures.

Key Features

- Designed specifically for E4D PlanMill systems

- Regulates internal temperature and minimizes friction

- Supports efficient and precise milling performance

- Helps extend the life of internal components

- Easy-to-use liquid formulation

Common Applications

- Routine maintenance of E4D milling systems

- Reducing wear on internal components

- Supporting optimal operating conditions during milling

Technical Specifications

Product Name: Milling Coolant Concentrate

Compatible Milling Units: E4D PlanMills

Container Type: Bottle

Manufacturer Name: Planmeca Inc

Package Quantity: 1/Pkg

Customer Ratings

Rating: 4.6 out of 5 (Based on verified reviews)

Customer Feedback

Users note improved milling quality and reduced machine wear when using this coolant regularly. Many appreciate its role in maintaining machine efficiency and reliability during daily operation.

9. MC Care Liquid

Product Description

MC Care Liquid is a specialized cleaning solution formulated for use with all Dentsply Sirona milling and grinding units. It plays a critical role in the wet cleaning process by preventing contamination and buildup in key internal components.

Product Overview

This liquid cleaner helps maintain optimal performance and longevity of the milling system. Regular use of MC Care Liquid reduces debris accumulation in the processing chamber, hoses, and spray nozzles, extending the service life of internal parts and supporting consistent system operation.

Key Features

- Designed for Dentsply Sirona milling and grinding units

- Prevents contamination and buildup in internal components

- Extends service life of chambers, hoses, and nozzles

- Supports efficient and hygienic milling operations

- Liquid format allows easy dosing and application

Common Applications

- Routine cleaning of Dentsply Sirona milling and grinding units

- Preventative maintenance to reduce internal wear

- Maintaining hygienic and efficient operation of dental mills

Technical Specifications

Product Name: MC Care Liquid

Product Type: Cleaner

Compatible Milling Units: Dentsply Sirona

Container Type: Bottle

Size: 250 ml

Manufacturer Name: Sirona Dental Systems LLC

Package Quantity: 1/Pkg

Customer Ratings

Rating: 4.7 out of 5 (Based on verified reviews)

Customer Feedback

Clinics report improved machine hygiene and reduced downtime when using MC Care Liquid regularly. Users appreciate its effectiveness in keeping components clean and extending the unit’s performance.

10. Filter Fleece for Wet Milling for PlanMill

Product Description

Filter Fleece for Wet Milling is designed for effective filtration in Planmeca PlanMill 50 S systems. These fleece filters trap debris and fine particles during the milling process, ensuring a clean and efficient workflow.

Product Overview

Used specifically for wet milling operations, the filter fleece helps protect internal components of the milling unit by capturing particulates before they can cause buildup or damage. This contributes to longer equipment lifespan and more consistent milling outcomes.

Key Features

- Engineered for use in wet milling environments

- Captures debris and particulates to protect internal systems

- Maintains clean operation for optimal performance

- Helps reduce maintenance frequency

- Compatible with PlanMill 50 S units

Common Applications

- Filtration during wet milling procedures

- Protecting internal components of PlanMill systems

- Routine maintenance and system upkeep

Technical Specifications

Product Name: Filter Fleece for Wet Milling for PlanMill

Product Type: Filter

Compatible Milling Units: PlanMill 50 S

Manufacturer Name: Planmeca Inc

Package Quantity: 5/Pkg

Customer Ratings

Rating: 4.6 out of 5 (Based on verified reviews)

Customer Feedback

Users appreciate the reliability and ease of replacement. Many report fewer issues with contamination and longer performance cycles for their milling units.